Growth from the 1780’s – 1830’s

The demand for stone increased hugely through the 19th century and Rossendale quarry owners responded to this by developing larger and larger quarries.

Poor rate books and documents from the Lloyd estate in Whitworth suggest the industry was growing from the 1770’s. Lots of the wharfs on the Rochdale canal were selling ‘Rochdale Flags’ and it is believed these were transported from the Whitworth quarries probably down Rooley Moor Rd. The 1848 map illustrates several large quarries throughout Rossendale but most in Whitworth. The map also indicates early mechanisation with several stone rubbing mills near streams.

Faster Growth in Late Victorian Times

Industrial development grew tremendously through Victorian time and with it the demand for strong building stone. Local growth was rapid and the coming of the railway in the 1840’s provided a major impetus, and the stone could be marketed more widely to large Victorian towns and cities. Destinations included Manchester, Preston and Liverpool, Part of Yorkshire, Birmingham and London, including Trafalgar Square. Thousands of tons of paving stones were transported out of the valley every year. Other products in demand were building stones for terraces, mills, churches, kerbs, setts, engine beds, flags for house and mill floors, pavements, railway platforms and dock sides.

The Rossendale stone industry mushroomed and the main entrepreneurs were the large companies of Henry Heys, Brooks and Brooks and Siddalls. They created a highly organised industry on the moor edge and moor tops.

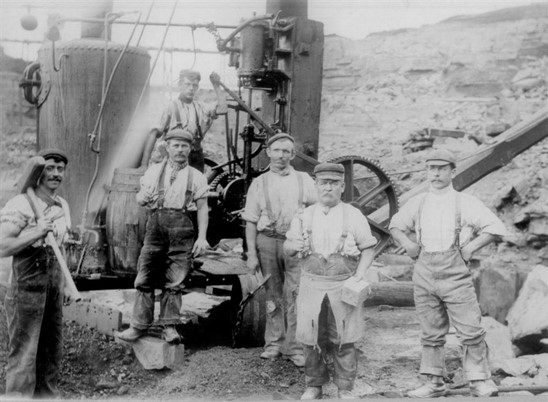

Quarrymen with steam crane and thier tools

Bacup Chronicle April 1902 “The stone industry of Rossendale has marvellously developed during the last fifty years, but at no period of it, more so than in the last decade, especially on the Brandwood side .....So that a good portion of the hillside and moor, extending over a radius of five or six miles is studded with gib cranes and refuse heaps.” (Messrs. Heys) has a huge stone sawing machine or ‘cutter’ here (Back Cowm), a facing machine and polishing machines at Facit...Near the Cowm quarries Messrs Heys have also a coal pit, the mineral from which is mainly used for their own steam cranes and engines. This firm have also quarries at Hapton, near Burnley, and it is very probable that they are among the largest quarry owners of the North.

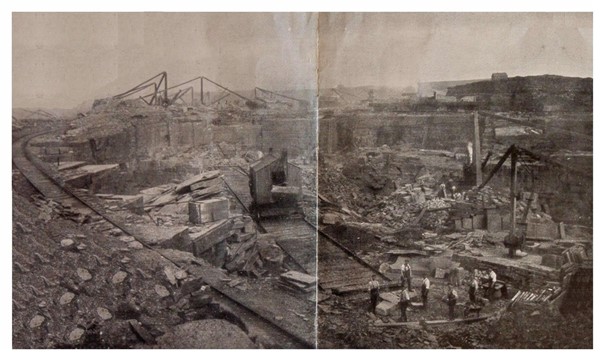

The scale of the activity was so intensive that these large companies drastically altered the landscape of the moor top, a bustling mass of cranes, workshops, tramways and workers.

Bacup Chronicle April 1902 again “On this side (Stacksteads) the whole face of the landscape has been greatly changed within the past few years, and one is bound to say not for the better from an artistic point of view. The rubbish first tilted down the gullies is now being heaped up to a height which gives the landscape an awfully weird and unattractive appearance.”

In 1888, a Bacupian visiting Back Cowm received: "one of the surprises of my life...Not having visited the place for over 30 years, I went the other day, but could not find a single landmark of my youth. Standing on the slope of the hill, looking across the valley at the magnitude of the undertakings there, I tried to count the number of steam and hand cranes, but it was impossible.”

Massive scale of activity in Siddalls Quarry, thought to be Back Cowm

It is estimated that at the peak around 1890-1900, 3000 men were employed in the Rossendale quarries, an enormous scale of activity and the third largest employer in Rossendale after textiles and footwear. In the heyday 3 stone trains a day left Britannia sidings, and it is estimated 2000 tons of stone a week left Stacksteads.

Henry Heys (1815 - 1889)

Quarry master Henry Heys is credited as the first man to successfully work the hard 'lonkey' beds - a rock so hard that previous quarrymen had failed. Excerpts fom his obituary notice in Bacup Times emphasise this.

"Mr Heys overcame what appeared to be physical impossibilities and uncovered untold mineral wealth which up to that time had been considered impossible to make into a saleable commodity ........he had gradually increased that employment........Mr Heys has developed the stone quarrying business of this district in excess of anything ever anticipated.........Mr Heys was the first to introduce steel wedges, which have been such a boon to quarrymen, not only in this district, but in other districts, enabling them to overcome the resistance which the mineral had hitherto offered to iron wedges. Previous to Mr Heys' time strong rock had been got with 'plug and feather', a very unsatisfactory operation compared with the clean splitting steel wedges of the present time".

Although Heys could not read and signed his name with a mark, he had the remarkable ability to calculate and estimate yardages of stone to complete buildings. At India Mill, Bacup, he correctly assessed and measured up the stone requirements in a couple of hours. An astonished surveyor hired by the mill owner, said it would take three weeks to do that sort of measurement.