The 19th Century was a century of rapid change with the growth of manufacturing industry and urbanisation. The turbulent changes contributed to a great deal of social problems and suffering. In the 1840’s the Chartist movement was fundamental to raising the nations consciousness to the poverty and exploitation of the urban working class. The Irish famine began in 1846 leading to a large influx of people from Ireland to the UK and the cholera epidemic in 1848 exacerbated the difficult living and working conditions of the poor.

Life of the Quarry Men in the 19th Century

One only has to look at an aerial photograph of Rossendale to see enormous holes cleaved out of the landscape, some of these holes are kilometres in scale. When one researches into the origin of these vast pits and discovers that they were stone quarries dug by hand and rudimentary tools a sense of awe can be the only rational response to such herculean effort.

The families of quarrymen came from all parts of the country and Ireland. During the 19th century Lancashire had the largest influx of people seeking work. On the 1881 census people from rural areas such as Cambridge and Norfolk came to Lancashire for employment, but by far the largest number came from Ireland 209,895 are recorded.

Often the men would arrive first to establish themselves before their families followed. We found that five men born in Ireland were residing at 5, Taylor Holme, a cramped back to back in Stacksteads, all the men were employed in the quarries.

Their names were Thomas Burke aged 32, Anthony Docherty aged 30, James Docherty aged 30, William Hynes aged 22, James Lyons aged 25 and James Monday aged 20 in the year 1881 . In total 22 Irishmen were living in the streets Taylor Holme and Taylor Terrace in Stacksteads. They were part of a group of men who would literally shape the skyline of Rossendale.

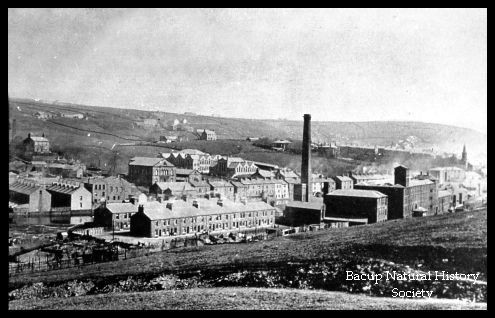

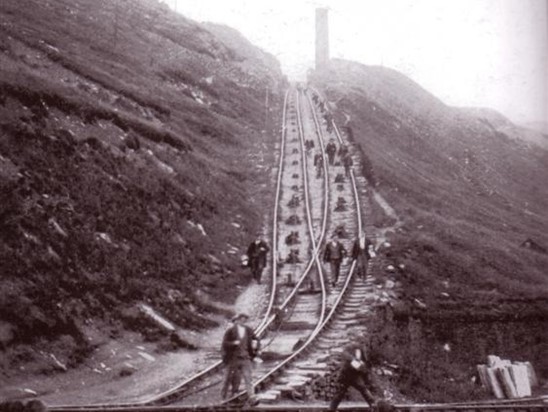

In the late 19th Century and early 20th Century the moor tops of Rossendale would have been busy with up to 3000 men working amongst a forest of steam and hand cranes. The quarries, which are now quiet places of contemplation, would have been places of industrious activity, with an intricate transport system consisting of a network of tramway lines. The stone was transported to sheds for cutting and polishing and then down to the main line railway, to provide the foundations and pavements of Victorian and Edwardian Britain.

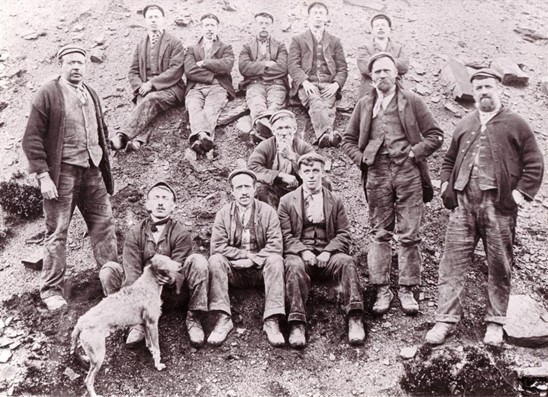

Every day hundreds of quarrymen would set off to work from the valley bottom and climb the steep inclines. Their jackets, waistcoats and trousers would be made of heavy moleskin or corduroy to keep out the wind with a simple knotted neckerchief, that was often useful as a bandage for slight injuries or wiping their sweating brow. In their group photos they are often seen with a determined countenance smoking a clay pipe.

They wore iron shod clogs on their feet and in their hands would be their brew can and food for the day. The men would heat their ‘bait or ‘baggin’ on a simple stove, in one of the dry stone shelters they built near to their workplace.

The men worked with hand tools in the open moorland with no safety equipment, using only hammers, picks, crow bars and sledge hammers forcing the stone from the rock beds. Imagine the effort of swinging a large sledge hammer all day, it was often said that ‘you would never see an overweight quarryman’, and the hard physical labour ensured that was the case.

The large pieces of rock from 1 to 7 tonnes would then be lifted by a steam crane to the work areas where they could be split again into manageable sizes and the banker masons could finally shape the sandstone to the correct measurements.

The constant use of their chisels on the hard Haslingden Flagstone would soon blunt their tools and they would have to visit the quarry blacksmith to get the tools sharpened again. The blacksmith was a highly skilled craftsman not only sharpening chisels but also making parts for any number of machines.

The quarry was a dangerous place with numerous heavy blocks of stone being lifted and transported daily. In January 1878 William Holden, employed at Mr James Walton’s, Horncliffe Quarries, was killed. William Holden was in the act of assisting to hoist a large stone weighing upwards of five tonnes, upon a wagon, and had already raised one side of it so as to let it rest upon the wagon, when the weight of the stone, being all on one side, caused the wagon to move, and the stone fell back onto the unfortunate man, killing him instantly. Sadly these incidents are not rare and the newspapers of the time are littered with similar fatal accidents at quarries or in stone mines.

The men would generally work in small teams, they would work out of doors with little shelter other than a small dry stone shelter (in other areas known as a 'Coe'), and at approximately 1100 feet above sea level the strong Pennine winds and sweeping rain would undoubtedly test their resilience and local folklore has it that ‘they were a tough breed’.

In 1908 a man named Foy was crushed between two railway wagons, in shunting operations. He walked home with assistance, to Yate Street, Bacup and was seen by Dr. Brown, who found he was in such a serious condition that to move him to the Infirmary would have brought about his death. He survived until seven o’clock that evening. At the inquest it was stated that the deceased had walked from Back Cowm quarry to Yate Street, Bacup, in a condition as stated by his doctor; the coroner, in his summing up said: “Foy was a hard one”.

If the men were lucky enough to avoid being killed or maimed due to accidents in the quarry there was also the distinct possibility that they would develop silicosis, a serious lung disease due to the silica content of the rock. Silicosis can lead to shortness of breath, fever and eventually death.

The men were paid by how many yards they could produce even the inclement weather would not stop them earning a wage for their families. It was only during severe winters when the men couldn’t work because the rock was difficult to get and shape they received no pay. Whether you worked as a Navvy, a rock getter, a mason, steam engine driver, crane driver or blacksmith, once the snow had fallen, work was suspended until it thawed and this would often lead to hardship for the families of quarrymen.

In 1907 soup kitchens at the Liberal and Beaconsfield clubs were set up to distribute soup and hot dinners to the out of work quarrymen and their families. The men had been unable to work because of the frost for six weeks.

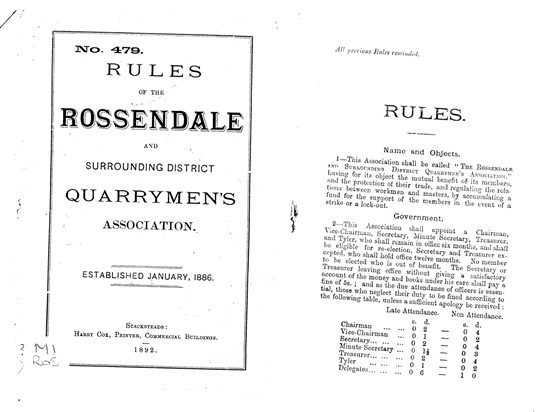

The very poor wages and dangerous harsh conditions led a group of men to form the Rossendale and Surrounding District Quarrymen’s Association in January 1886, although their combined actions and struggles had little impact on their ‘pay packet’. By 1919 between 400 and 500 quarrymen from Whitworth and Stacksteads were on strike because although an advance of 100% on pre war rates, had been granted, the quarrymen were still getting less than youths of 17 years of age, working in the mills.

At the time there was a growing Temperance movement, and Rawtenstall has one of the remaining temperance bars left in the country, yet the quarrymen would not be willing converts. It seems that beer was the beverage of choice to slake the quarryman’s’ thirsts and wash the stone dust from their throats, according to the many incidents of public order offences due to quarrymen being intoxicated. In fact they even had to levy fines for Quarry Union members that turned up to meetings drunk. The fine for attending the lodge meeting ‘intoxicated and turbulent’ was 1d, for the first offence, for the second offence it was 6d.

Find out more by watching the video the 19th Century Quarrymen here, produced by young people as part of the CAR Video Unit project.

Life of a Quarryman the 20th Century

Just before the second world war the life of the quarryman hadn’t changed much. In 1939 boys of 14 or 15 would start work in the quarries and would be paid only 6d an hour. The wage would be less than employment in a weaving shed or spinning mill but the young lads that went into the quarries preferred the outdoor life and wanted fresh air in their lungs. Their first jobs would be general lifting and carrying, for instance they would load the Jubilee’s with scaplings (waste from pitching the stone) from the mason’s ‘hillocks’. The scaplings would go to the crusher to be ground down to different grades of stone to make concrete products, donkey stones or sometimes ‘water bound’ roads.

Other tasks for young men included working as an assistant to the Blacksmith (Smithy), this would include carrying a cow-hide bucket to the hillocks to collect the masons’ blunt tools. They could also make a bit extra on their wage packet by making tea for the men (brewing up) and keeping the hot plate stocked with finest Yorkshire steam coal or shale coal from around the site.

There was no formal apprenticeship to become a mason, each individual would learn how to use the different tools one at a time from the hacking hammers, dressing hammers, special chisels like pitchers and Points. First they would attempt to put a draft (The tooeled margin round the face edges of a roughlysquared stone, usually about 3/4 inch wide) or margin along the edge of a piece of stone with a chisel, then they could move on to the ‘point’. The quicker they learnt the trade the more money they could make and it was often technique rather than brute strength. The skill would come with experience and everything was done with what they would describe as ‘the rack of the eye’ looking carefully at something and using judgement to make an informed decision. There were very few health and safety regulations, so if they decided to lift a 10 tonne block of stone with a steam crane they had to get it right or lives were in danger.

Each team of masons worked on a hillock with a ‘Lumper up’ a person who would make the first cut in the stone, he would decide how best to split the rock, it would then be divided up and lifted to the banker benches for the masons to finish off the product whether it was a, 12 x 8 curb, channel or edging etc. Every fortnight the foreman would measure with a 50 yard tape how much dimensioned stone had been produced and calculate their wage. The money would then be divided between the group of masons, usually in a local pub such as the Royal Oak.

The unions had negotiated for the quarrymen, what they called ‘wet- time’ a percentage of their wage for time spent when they couldn’t work because the rain made conditions dangerous.

The men would still be taking their food in a ‘Tommy box’ and warming their food on a hot plate in a cabin. The ‘Tommy box’ would also stop the sheep getting at their lunch because they were known to push the cabin door open and eat the men’s sandwiches if they were not in a secure place.

Post second world war the quarries were in decline and in 1960 there were only 5 masons working in Britannia quarry and two rock getters. Steam cranes were still in operation but diesel cranes were introduced and it took a skilled plant fitter and his apprentice to maintain the variety of machines now employed in the quarries and keep them working. Stone was still selectively being taken out by hand and the rock getters still used two-man crow bars to manipulate large blocks of stone before they were split into smaller blocks using the plug and feather method.

Young men would be employed from the age of 15 and the work was still hard in damp dreary conditions during the winter months but from the 1950’s onwards quarries became more health and safety conscious and improved facilities were provided.

Flags continued to be sawn when required, but the largest percentage of production would now rely on blasting to produce aggregates, mainly for the new motorways that were being built during the 60’s. The quarries from the 1960’s became increasingly more mechanised and enormous earth moving plant would be used to get, lift and crush the stone.