Planing stone

As the demand for Rossendale flagstones increased during the second half of the 19th century, quarry owners sought ways of producing flagstones as quickly and cheaply as possible. Once the stone had been quarried, the main task in making a flagstone was to give the top a flat surface. A new way of doing this was introduced in the 1870s in the form of stone planing machines or “steam masons”.

This was a time of advancing mechanisation. By the 1800s machines to replace the lighter craft skills, such as spinning and weaving, were already well established. But now the technologies of machine making had developed so that bigger, stronger and more complex machines could be built. This meant that heavier craft skills such as those of the millwright, stone mason and even machine making itself became candidates for mechanisation.

Machines for planing smooth flat surfaces on iron components were commonplace by the middle of 19th century. Amongst those attempting to achieve the same with stone were James Coulter and Herbert Harpin of West Yorkshire. In their application for a patent in 1872 they state “our invention relates to improvements effected by us in the ordinary planing machines for iron in adapting it for cutting stone”. In other words, they took the established process of planing iron and modified it to work successfully on stone. They had created a stone planing machine. Further patents for refinements and variations followed over the next 20 years and Coulter and Company of Bankfoot Foundry in Batley, West Yorkshire, became an established supplier of stone planing machines.

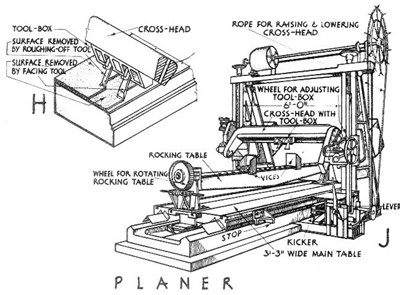

These machines were driven by steam and were known by a number of names such as “Drovers”, “Flag Facers” and “Steam Masons”. The name “Steam Mason” is particularly apt because the machine worked by pushing the top of the flag against a tool like a chisel, so that it removed a thin layer of stone in much the same way that a mason would do with a hammer and chisel. After the tool had passed along the full length of the flag, the tool was moved sideways for the next pass. This was repeated until it had planed the full width. To speed up the process, planing machines usually had several tools cutting the stone at the same time.

VR of a Planing Machine or Drover

These machines became an integral part of steam driven stone processing. In 1929 Henry Heys and Company had ten planing machines and Siddalls at Stacksteads had eight machines at the close of the firm in 1915.

In Rossendale these planing machines were used principally to face flagstones, but in other areas, where the stone was more easily shaped, they were used to produce shaped stone components, such as cornices and window jambs. To facilitate this fancier work the machines were equipped with a rocking table. This is the type of machine described in Building Construction by W B McKay, first published in 1944. This text book was widely used by students of building and architecture in the decades following its publication and has now been re-published by Donhead Publishing Ltd.

In Rossendale these planing machines were used principally to face flagstones, but in other areas, where the stone was more easily shaped, they were used to produce shaped stone components, such as cornices and window jambs. To facilitate this fancier work the machines were equipped with a rocking table. This is the type of machine described in Building Construction by W B McKay, first published in 1944. This text book was widely used by students of building and architecture in the decades following its publication and has now been re-published by Donhead Publishing Ltd.