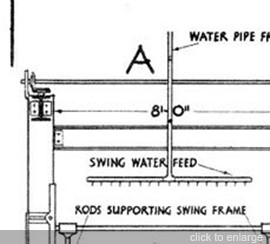

Click to see a description of a frame saw taken from Building Construction by W B McKay, first published in 1944. This text book was widely used by students of building and architecture in the decades following its publication and has now been re-published by Donhead Publishing Ltd.

Reproduced by kind permission of Neil McKay and Donhead Publishing Ltd.